Features

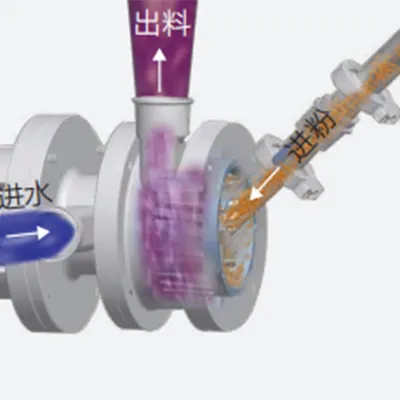

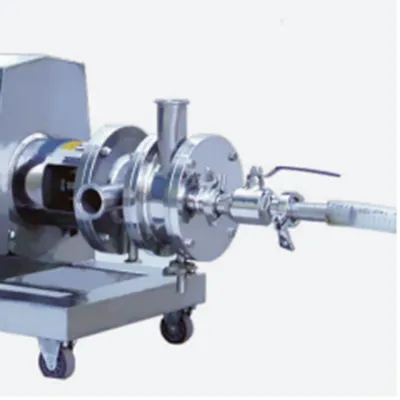

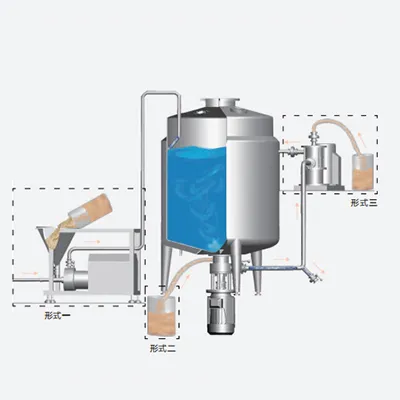

The powder liquid mixer features fast powder suction, which speeds up the overall process and reduces energy consumption, making it a cost-efficient solution. Its hygienic design ensures that powder is fed without generating dust, which minimizes contamination risks and creates a cleaner working environment. One of its key advantages is its ability to prevent clumping, especially for powders that tend to expand when in contact with liquids. This ensures that the powder is uniformly wetted and dispersed immediately upon contact, eliminating the need for additional mixing steps. Additionally, the modular design allows for seamless integration into existing systems, reducing both equipment investment and long-term production costs.

Applications

The PLM system finds applications across various industries due to its versatile capabilities. It is ideal for dissolving powdered milk, fruit milk, and yogurt ingredients directly in-line within the production pipeline, allowing for efficient, high-speed mixing of ingredients. It also excels at dissolving supersaturated sugar solutions, a critical process in the food and beverage industry. The system handles challenging tasks such as dissolving gums like CMC (carboxymethyl cellulose), carrageenan, and pectin with ease, ensuring complete dispersion without agglomeration. In addition, it provides excellent performance in the homogenization and dispersion of cereals and starch with water, as well as in the high-speed mixing of concentrated tea powders and fruit juices. Beyond the food industry, the PLM is particularly effective in dispersing and mixing nanomaterials such as silica, titanium dioxide, and kaolin, making it valuable in sectors that require the dispersion of fine powders and particles.