Dispersion of artificial sweetener for soft drink manufacturing

Client Background

The client is a producer of artificial sweeteners, which are essential for creating low-calorie, sugar-free soft drinks, or diet soda. Ingredients like aspartame, acesulfame-K, and saccharin are costlier than traditional sugar, but their concentrated sweetness means they are used in smaller quantities. As the demand for healthier beverages continues to grow, the need for these sweeteners is on the rise.

Challenges

Artificial sweeteners do not replicate the texture and consistency of sugar-based formulations and thickeners like CMC (carboxymethyl cellulose) are often added to it for compensation. However, traditional mixers struggle with the long mixing times required to properly disperse, and dissolve these ingredients. Powders like caseinate and milk powder are highly viscous and prone to clumping, making them difficult to break down with conventional mixers. Caseinates are notoriously hard to dissolve, and insufficient shear forces prevent the formation of a stable pre-emulsion needed for high-pressure homogenization.

Our Solution

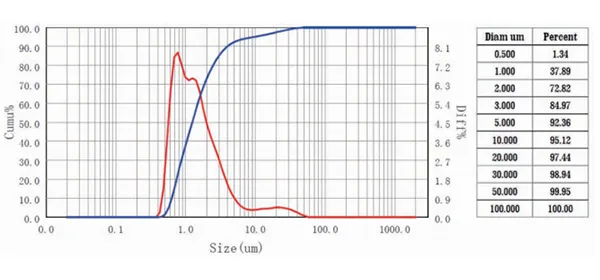

By using our inline high-shear emulsifier, the sweetener and thickening agents are effectively refined, addressing the issue of uneven particle size distribution. This ensures no clumping, significantly reduces mixing time, and produces a stable pre-emulsion. The emulsifier system’s strong suction force enables rapid dispersion of aggregates, speeding up dissolution and ensuring uniform mixing.

Final Results

The refinement process required only two passes through the high-pressure homogenizer after using the inline shear mixer. This reduced the total processing time by 50% compared to traditional mixing followed by homogenization. The narrow particle size distribution and the efficient processing of 100% of the material through the shear chamber improved overall efficiency and product quality.

The specialized mixing equipment offered By FLUKO ensures precise, fast mixing and dispersion for the food and beverage industry. Our dispersion and emulsifying solutions help manufacturers enhance product consistency, reduce production time, and stay ahead in a competitive market.