Emulsifying and mixing for battery slurry preparation

Client Background

The client is a lithium-ion battery manufacturer. In lithium-ion batteries, the cathode slurry consists of binders, conductive agents, and cathode materials, while the anode slurry includes binders and graphite powders. Preparing both slurries involves mixing and dispersing liquid-liquid and liquid-solid materials under strict conditions, such as changing temperatures, viscosities, and environmental factors.

Challenges

The dispersion and uniformity of particulate active materials in both the cathode and anode slurries directly affect the movement of lithium ions between the battery’s electrodes. Proper mixing and dispersion of the electrode materials are critical to the quality and performance of the lithium-ion battery. Achieving thorough mixing and dispersion of high-viscosity materials under vacuum conditions is a significant challenge.

Our Solution

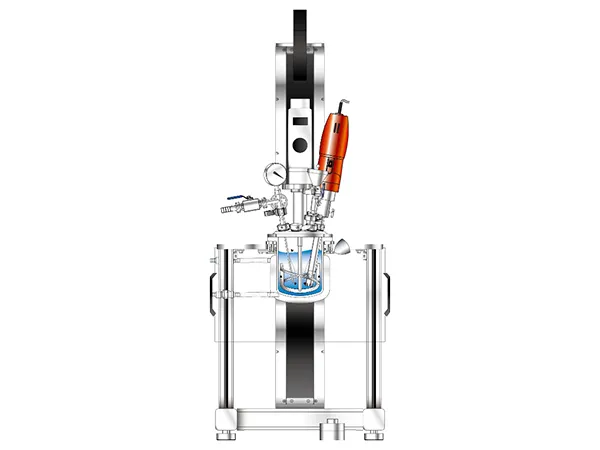

The Fisco-1S full cell reaction system by FLUKO addresses these challenges by incorporating a high-shear emulsifier with rotational speeds ranging from 10,000 to 28,000 rpm and a maximum linear speed of 27 m/s. Paired with a 3D anchor-style helical ribbon agitator, this emulsifying system enhances mass and heat transfer for the high-viscosity slurry, ensuring uniform dispersion. The vacuum environment inside the tank (-0.092 MPa) eliminates air bubbles that improves the quality and consistency of the slurry. Specialized homogenizing probes can be selected to further optimize its uniformity.

The emulsifying system ensures precise, efficient slurry preparation, optimizing battery performance and production consistency for the new energy industry.