FLUKO ® Eumix Agitators & Stirrers

Mixing heads for agitation and stirring

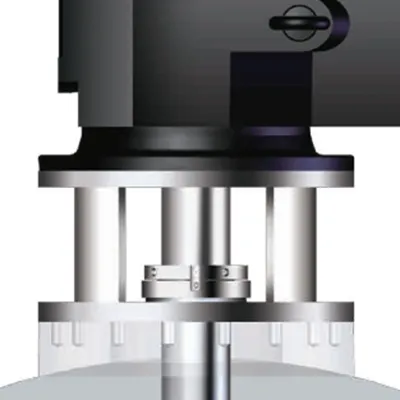

The cup agitator features a unique cup-shaped impeller with three blades strategically angled to compensate for one another, which allows for efficient axial flow within the mixing tank. This maximizes flow coverage, ensuring that even low-viscosity fluids are evenly distributed within the container. One of the key advantages of this design is its energy efficiency. The specially designed shape of the blades allows for a broader flow area with less power, which can be advantageous for large-scale, continuous mixing applications.

Applications

The impeller's cup-shaped design promotes rapid, uniform mixing of low-viscosity materials, making it effective for blending and dispersion tasks. While the cup agitator is primarily designed for low-viscosity mixing, it also provides sufficient shear to handle tasks such as dispersion and dissolution, delivering consistent and homogenous results for a variety of applications.

Specifications

- Motor: Normal motor/explosion-proof motor

- Speed: Constant speed/frequency speed control

- Applicable density (kg/m³): 800-1200

- Applicable viscosity (cP): 1-500

- Vessel volume (m³): 1-5

- Working pressure (Mpa): -0.03~2

- Working temperature (℃): 10-200

- Configurations

Material: depending on process requirements (temperature, pressure, corrosion)

Seal: oil seal, double mechanical seal Finish: mechanical polishing, electropolishing