Emulsifying and mixing for pesticide production

Client Background

The client is a pesticide manufacturer producing water-based emulsions, a common pesticide formulation where active ingredients that are insoluble in water are dissolved in an organic solvent and emulsified into small droplets (0.5-1.5 microns) within water. This creates a milky opaque oil-in-water (O/W) emulsion, a more environmentally friendly pesticide solution.

Process Flow

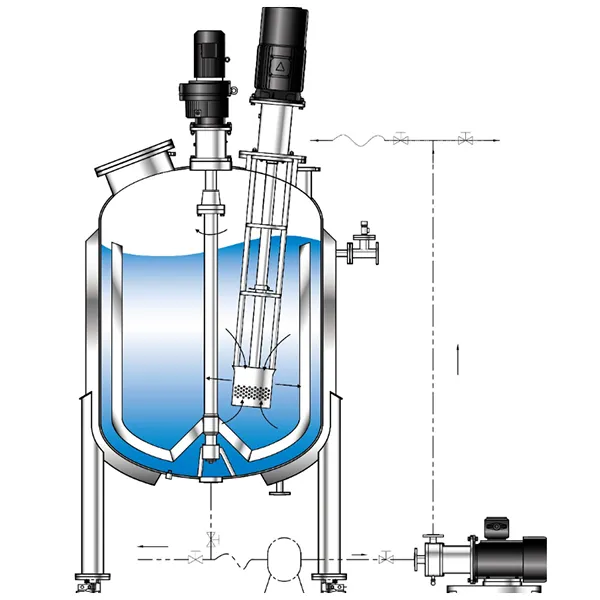

- Oil phase premixing: The pesticide's active ingredients and solvent are dispersed and dissolved.

- Water phase premixing: Water and surfactants are thoroughly mixed in a shear tank.

- Emulsification: The oil phase is introduced into the water phase using a high-shear emulsifier, which emulsifies and shears the mixture to form a stable emulsion.

Challenges

- Long emulsification period: Traditional equipment takes too long to emulsify the oil and water phases, resulting in low efficiency.

- Uneven emulsification: Uneven particle size distribution leads to an inconsistent mixture with wide size ranges.

Our Solution

- Batch high-shear emulsification: A high-shear dispersing emulsifier is installed in the emulsification tank to reduce the mixing process time.

- Inline high-shear emulsifier: By using an inline emulsifier outside the emulsification tank, energy density is concentrated in a narrow working chamber, ensuring no dead zones in the shearing process. This leads to a narrower particle size distribution, higher uniformity, reduced batch-to-batch variation, and improved product stability.

Our high-shear emulsification systems streamline pesticide production, ensuring precise particle distribution and superior product stability, helping chemical manufacturers increase efficiency and product consistency.

With our high-shear emulsification system, chemical manufacturers achieve faster production, enhanced product consistency and precise particle control, driving efficiency and reliability in pesticide formulations.