Emulsifying and mixing for fat emulsion production

Client Background

The client is a pharmaceutical manufacturer specializing in medical fat emulsions. These emulsions primarily involve dispersing and shearing soybean oil and lecithin to create nutrient-rich fat emulsions. The process requires using inline emulsification to ensure efficient mixing of oil and water tanks, rapidly reducing particle size to achieve a stable oil-in-water emulsion.

Challenges

While traditional high-speed mixing or rotor-stator high-shear systems can achieve oil phase dispersion, they often lack sufficient shearing force which leads to incomplete lecithin dissolution This can result in issues like floating oil and phase separation, which hinder the subsequent high-pressure homogenization stage. Achieving quick and uniform particle size reduction and ensuring lecithin is properly dispersed remains a major challenge.

Our Solution

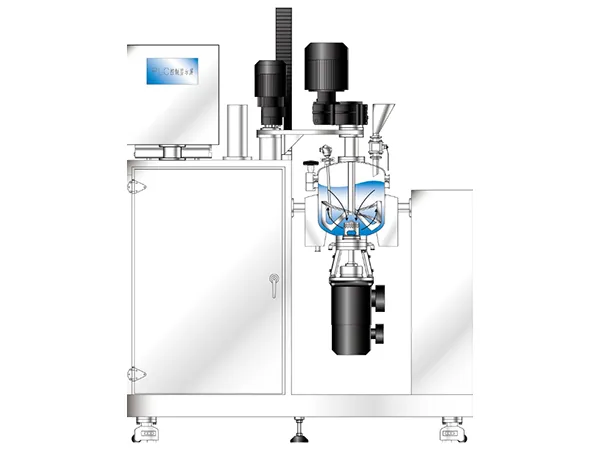

The pre-emulsion phase is crucial in the fat emulsion production process, where the oil phase and water are mixed to create a stable emulsion. FLUKO utilizes a three-stage inline emulsifier to ensure that the particle size distribution of the oil-water emulsion is uniform. This emulsifying system provides consistent shearing of the oil and water phases throughout the process. The small, three-stage shear chamber ensures thorough shearing without dead zones, leading to uniform particle size reduction and a stable emulsion.

Pharmaceutical manufacturers can significantly elevate their efficiency of fat emulsion production with our advanced dispersing emulsifiers. Our innovative technology ensures consistent quality and precision, delivering nutrient-rich emulsions with ease, while optimizing production time and minimizing costs. Our homogenizing solutions empower you to stay ahead in a competitive market, offering reliability and performance you can trust.